Description

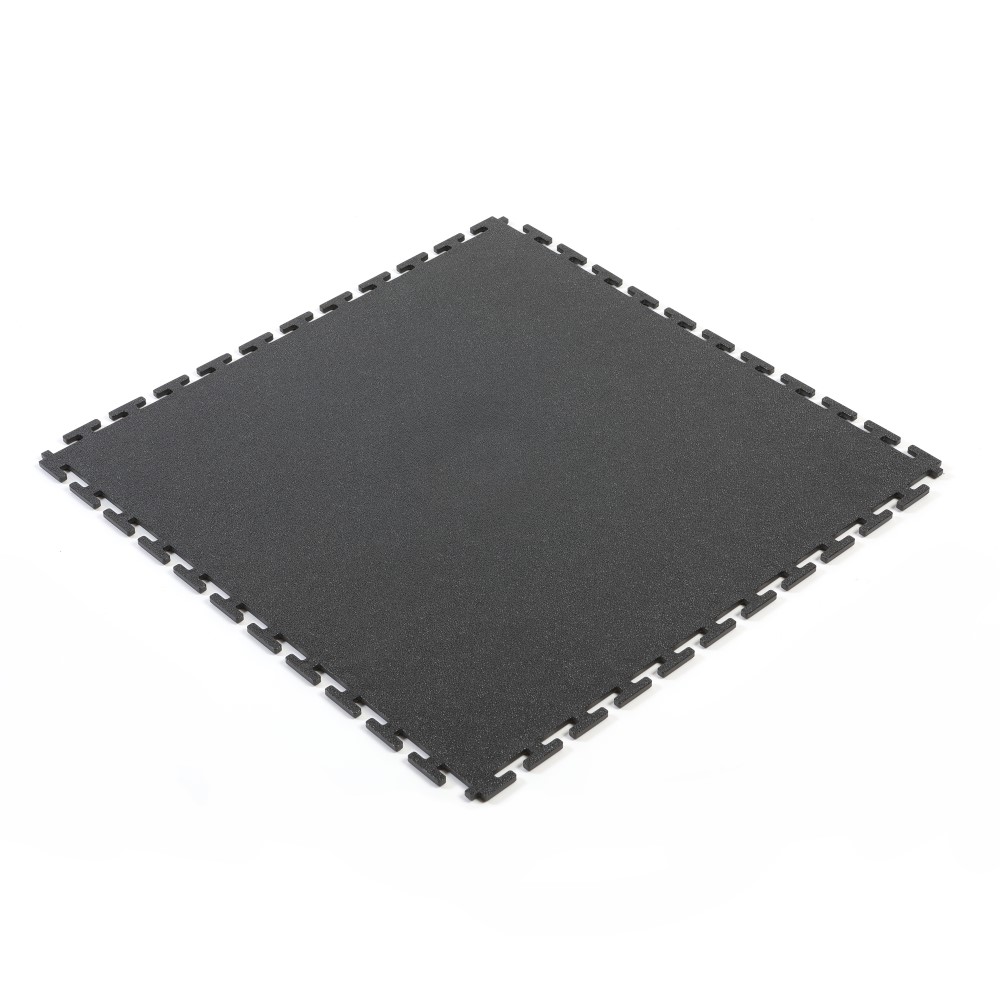

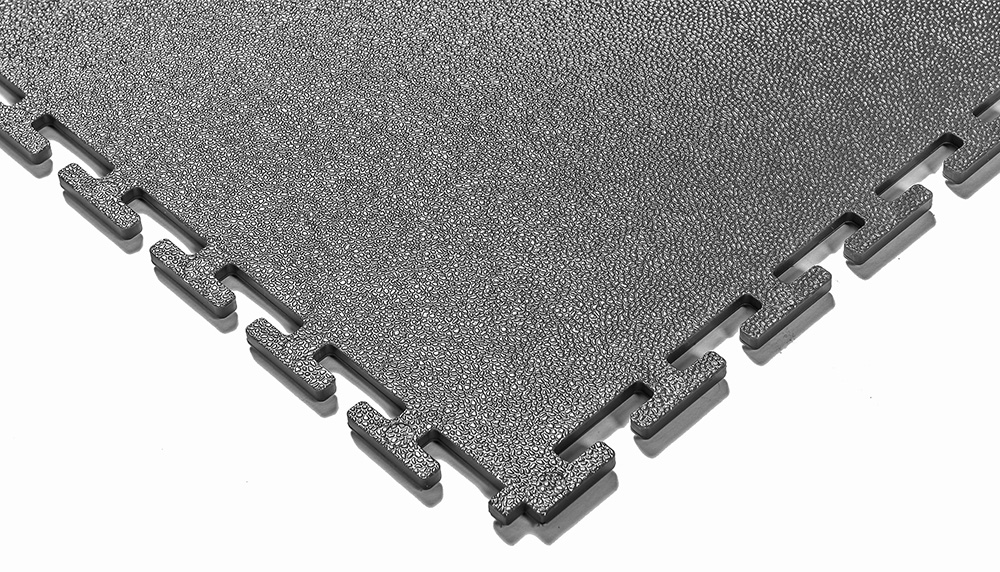

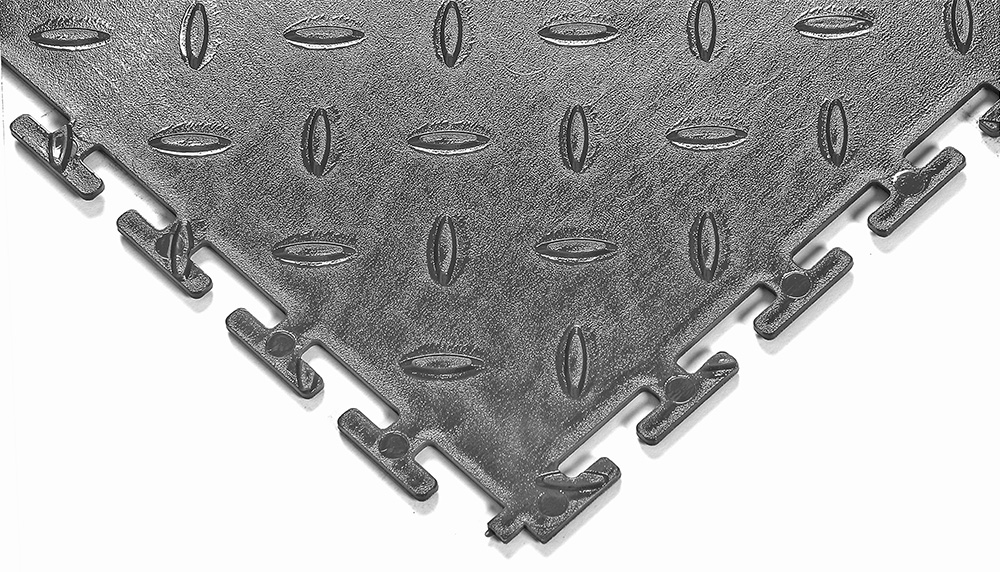

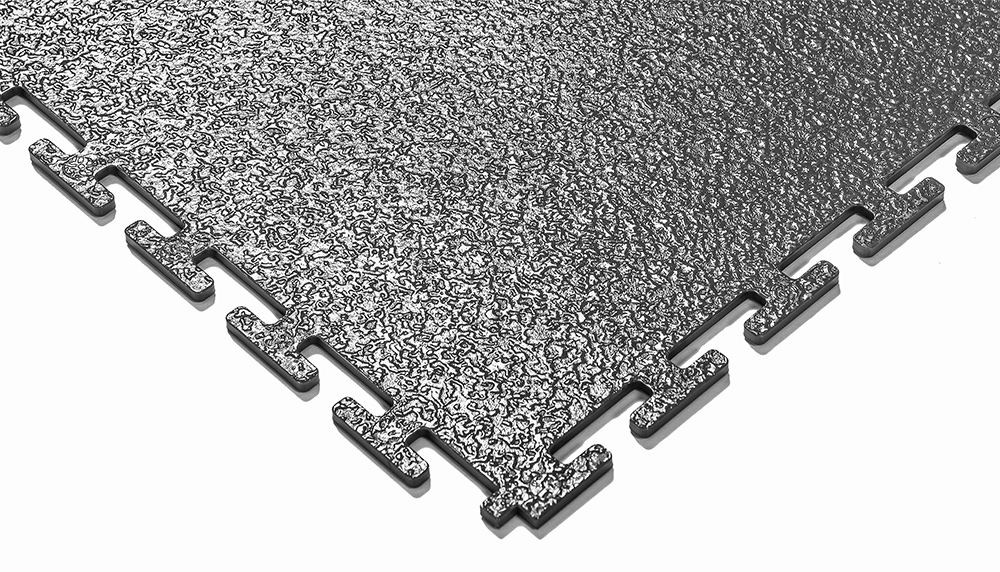

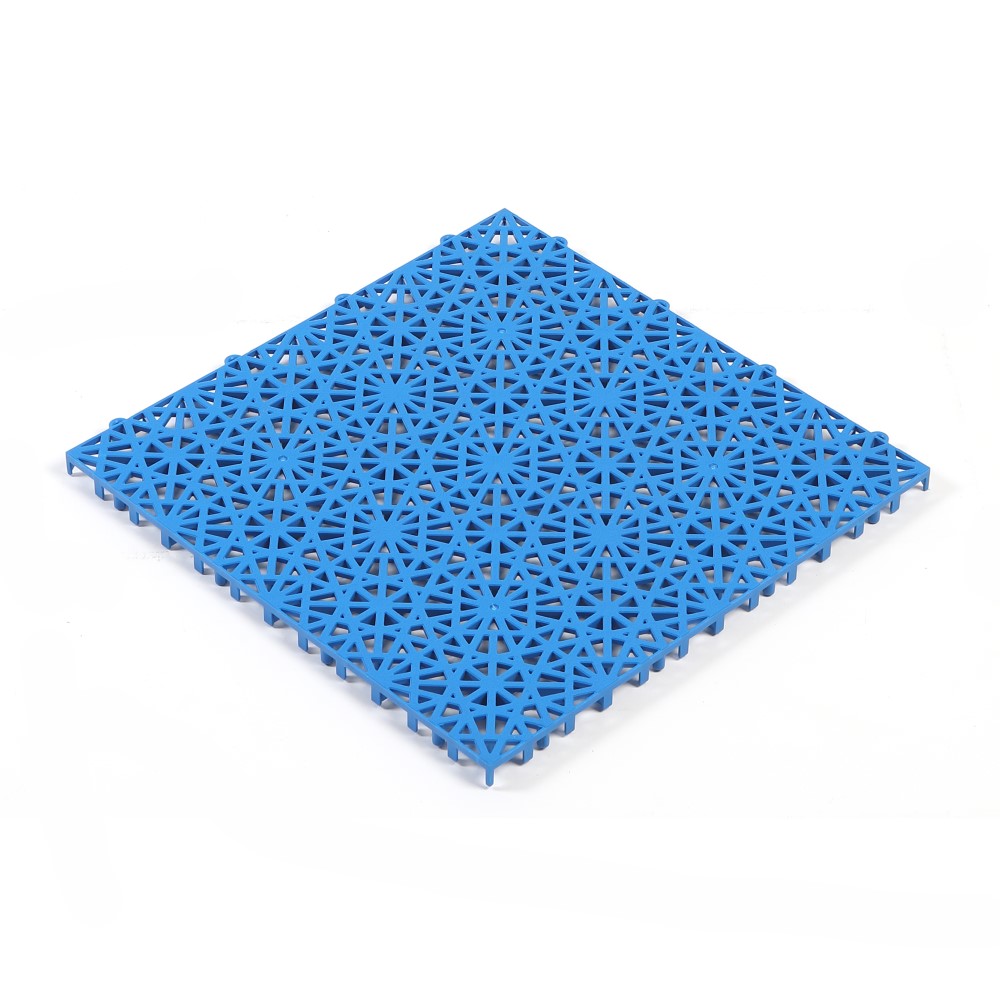

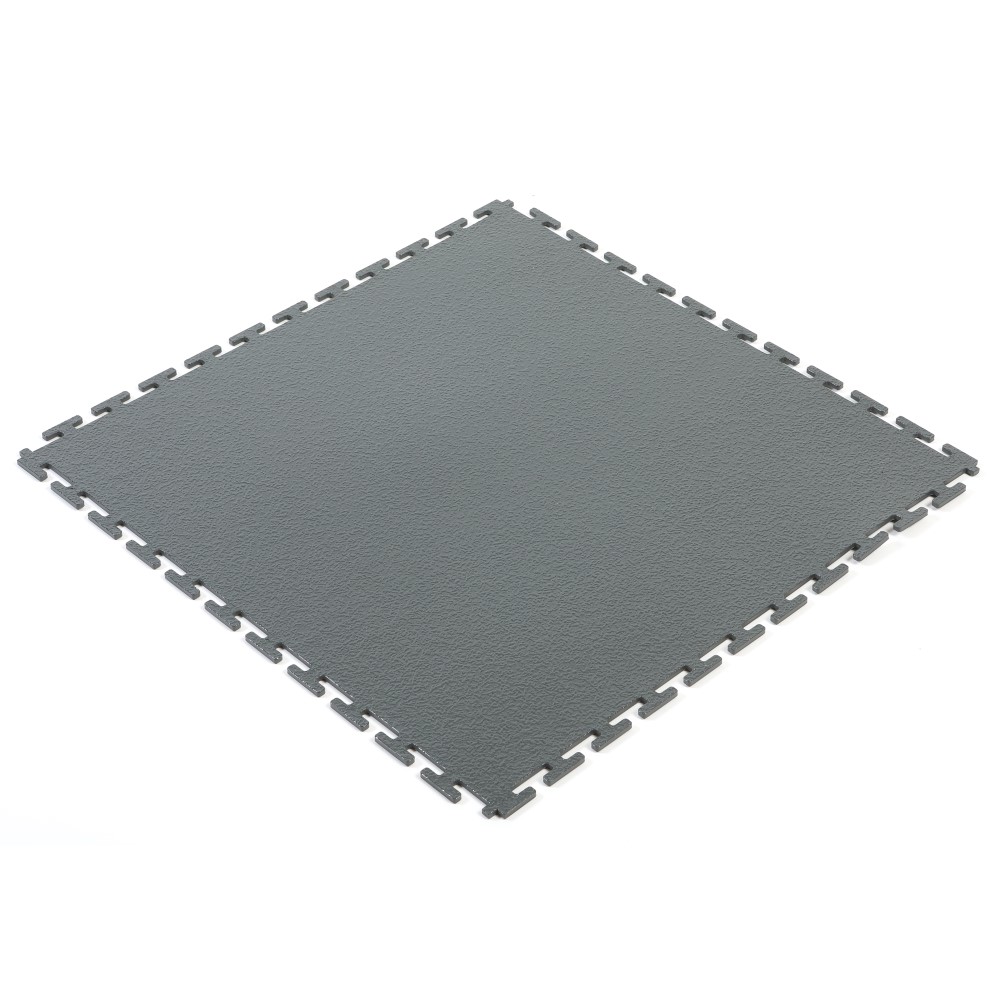

The Global Industry ECO is a 100% virgin PVC tile, environmentally friendly and durable, with an orange peel or a hammered finish that makes it anti-skid. Thanks to its interlocking system, installation does not require glue and is simple and immediate, even for non-professionals. Designed for industrial applications, this tile can withstand the traffic of motor vehicles and lifting trucks time after time. It breaks the fall of tools and other objects, reducing any risk of damages. Quick, glueless installation allows re-flooring without interrupting ongoing activities and without moving machinery and equipment. To maximise wear resistance, Esseciplast® tiles are protected with a special treatment, unique in Europe, with exclusive protective paints that boost resistance to abrasion and dirt, facilitate cleaning and preserve the beauty of your Esseciplast® floor over time.

The Global Industry model is available in various colours, but any RAL colour can be requested for surface areas above 100 square metres. The tile can also be customised with printed logos, path indications or markings. Available also in virgin PVC in 13 colors (any Ral color available on request).

Available colours

Grey

Black

Accessories available

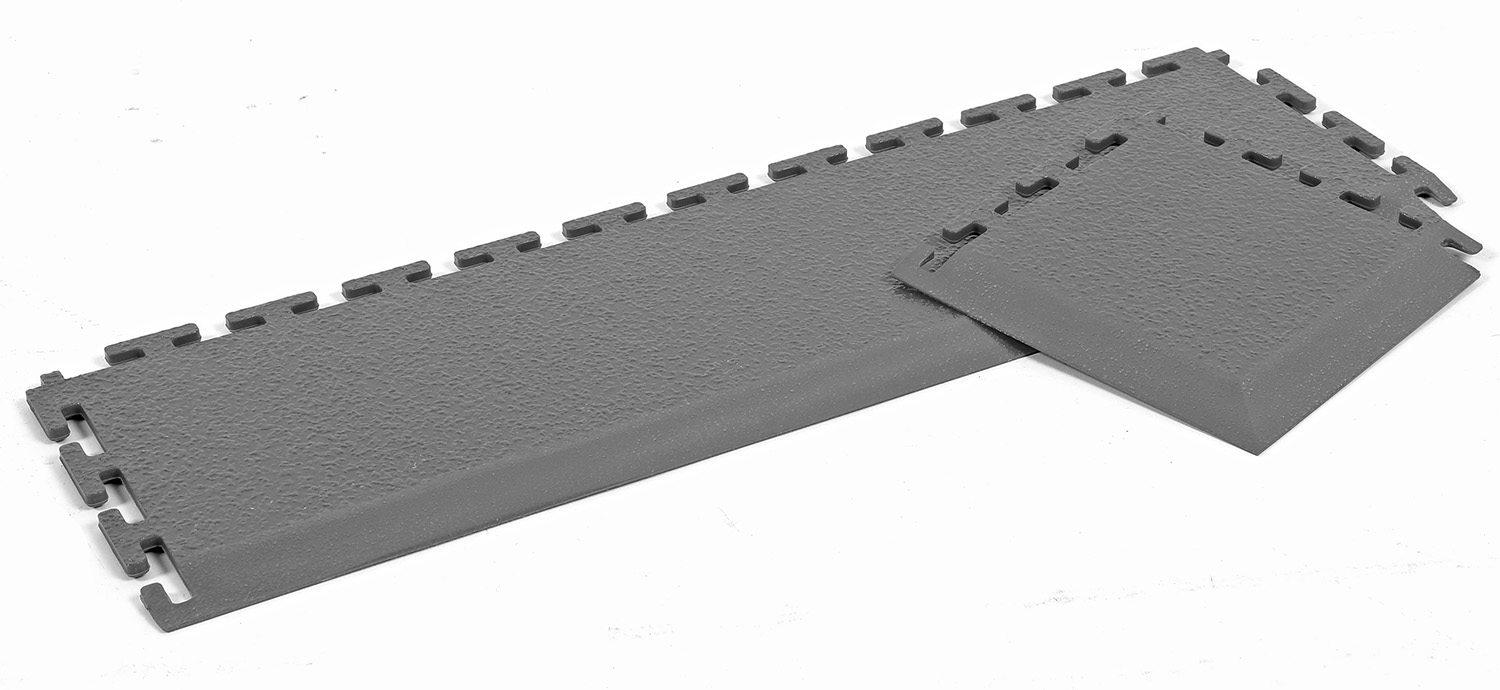

Ramp and Corner

Discover the most frequently asked questions about our Global Industry Eco tile

It means that we recover all the pieces of differently unusable tiles, such as the color changes of the mold (tiles that are faded from one color to another), the pieces cut for the poses or for the realization of the access descents or the tiles that show any slight aesthetic defect, we grind them and blend them, again producing tiles, which are called ECO. These tiles contain various colors of PVC so they can only be produced in dark colors, but they are of the same original material, simply re-transformed, therefore they have the same identical technical and aesthetic characteristics and the same certifications.

Special accessories are available with access ramps, but it is also possible to carry out this process directly on the edges of the tiles.

You can easily cut them with a professional cutter, but for large sizes the use of a laminate cutter is recommended.

No, no glue is needed, simply place them on the existing (level and clean) bottom and shape the tiles against the walls. In industrial application, depending on the model of forklifts and the steering points of the same, in some cases it may be necessary to glue some tiles so that the wheels, at the point of greatest traction, do not risk lifting the tile.